Why Mean Time Between Failures Matters for Reliability

Mean time between failures (MTBF) serves as a critical metric for assessing system reliability and operational efficiency. A higher MTBF reflects reliable equipment, fewer disruptions, and better maintenance planning. For example, scheduling preventive maintenance based on MTBF data minimizes unexpected failures and reduces costs. In customer-facing systems like Sobot's Voice/Call Center, this reliability ensures uninterrupted service, enhancing customer satisfaction. With a 99.99% system uptime, Sobot exemplifies how robust MTBF metrics build trust and improve operational outcomes. Reliable systems not only reduce downtime but also foster long-term customer loyalty.

Understanding Mean Time Between Failures (MTBF)

What is MTBF?

Definition and role of MTBF in system reliability.

Mean time between failures (MTBF) measures the average time a system operates before experiencing a failure. It serves as a key indicator of system reliability, helping you predict how long your equipment or software will function without interruptions. A higher MTBF reflects a more reliable system, reducing the likelihood of unexpected breakdowns. For businesses, this metric is essential for planning maintenance schedules and ensuring smooth operations.

In customer-facing systems like Sobot's Voice/Call Center, MTBF plays a vital role. With a 99.99% uptime, Sobot ensures minimal disruptions, allowing your team to focus on delivering exceptional customer experiences. By understanding MTBF, you can better assess the reliability of your systems and make informed decisions to enhance performance.

Common applications of MTBF in industries like customer service and contact centers.

MTBF finds applications across various industries, especially in customer service and contact centers. For example:

- Customer Support Systems: MTBF helps predict when systems like Sobot's Voice/Call Center may require maintenance, ensuring uninterrupted service.

- Manufacturing: An MTBF of 876 hours for an assembly line indicates moderate reliability, guiding maintenance teams to prevent costly downtime.

- Data Centers: Companies like BackBlaze use MTBF to track hard drive failure rates, optimizing reliability strategies.

By leveraging MTBF, you can maintain operational efficiency and reduce downtime in critical systems.

Why MTBF Matters

Connection between MTBF and system reliability.

MTBF directly impacts system reliability. A high MTBF means fewer failures over the system's lifetime, leading to consistent performance and reduced operational disruptions. For instance, General Electric Transportation Systems uses MTBF data to adjust reliability strategies, significantly lowering equipment failures. This approach ensures that your systems remain dependable, fostering trust and satisfaction among customers.

How MTBF predicts system performance and reduces downtime.

MTBF serves as a predictive tool for system performance. By analyzing MTBF data, you can identify patterns and schedule preventive maintenance before failures occur. This proactive approach minimizes downtime and avoids costly emergency repairs. In customer-facing platforms like Sobot's Voice/Call Center, high MTBF ensures seamless operations, enhancing customer satisfaction and loyalty. Reliable systems not only save costs but also strengthen your brand's reputation.

The Importance of MTBF for System Reliability

Benefits of High MTBF

Reduced downtime and operational disruptions.

A high mean time between failures (MTBF) ensures your systems experience fewer interruptions, leading to smoother operations. Reliable equipment with a high MTBF minimizes unplanned downtime, allowing you to maintain productivity and meet customer expectations. For example, IBM highlights that improving MTBF increases reliability, reducing downtime and boosting overall efficiency.

| Source | Claim |

|---|---|

| WorkTrek | A high MTBF in manufacturing can lead to less downtime and lower costs. |

| Pure Storage | A high MTBF shows that your system or component is highly reliable and will have fewer problems over its lifetime, translating to reduced downtime. |

| Brightly Software | A high MTBF indicates reliable machinery, leading to reduced downtime and higher productivity. |

| IBM | Improving MTBF can lead to increased reliability, helping businesses reduce downtime and improve productivity. |

Enhanced customer satisfaction through reliable systems like Sobot's Voice/Call Center.

High MTBF directly impacts customer satisfaction by ensuring consistent service delivery. Metrics such as equipment uptime and customer satisfaction scores validate this connection. For instance:

- Equipment Uptime: Reliable systems operate longer without failures, ensuring uninterrupted service.

- Customer Satisfaction Scores: Higher scores reflect improved experiences due to dependable operations.

- Reduced Maintenance Costs: Efficient systems lower costs, indirectly enhancing customer satisfaction.

Sobot's Voice/Call Center, with its 99.99% uptime, exemplifies how high MTBF fosters trust and loyalty by minimizing disruptions in customer interactions.

MTBF and Cost Efficiency

Lower maintenance costs with predictive insights.

Tracking MTBF metrics allows you to plan maintenance proactively, reducing labor costs and extending the lifespan of components. Preventive maintenance based on MTBF data avoids unnecessary repairs and ensures your system remains operational. For example, AI-driven predictive maintenance has achieved a 47% reduction in unplanned downtime, saving businesses $425,000 annually. Regularly reviewing MTBF metrics also helps allocate resources efficiently, ensuring seamless operations.

Avoiding costly emergency repairs or replacements.

A high MTBF reduces the likelihood of sudden failures, saving you from expensive emergency repairs or replacements. By understanding MTBF, you can budget effectively and minimize downtime-related revenue losses. For instance, leveraging connected CMMS systems for asset monitoring improves workforce scheduling and prevents unplanned downtime. This approach safeguards your operations and ensures financial stability.

MTBF in Customer-Facing Systems

Ensuring consistent service delivery in call centers and support platforms.

In customer-facing systems like Sobot's Voice/Call Center, MTBF plays a critical role in maintaining uptime and reliability. Metrics such as uptime percentage and mean time between failures validate the impact of MTBF on consistent service delivery:

| Metric | Description |

|---|---|

| Uptime Percentage | Reflects the percentage of time equipment is operational, indicating effective maintenance and reliability. |

| Mean Time Between Failures | Indicates average time between failures, showing equipment reliability and maintenance effectiveness. |

These metrics ensure your call center operates smoothly, providing uninterrupted support to customers.

Building customer trust through reliable operations.

High MTBF enhances customer trust by reducing system failures and ensuring dependable service. Customers value reliability, and consistent operations foster loyalty. For example:

| Benefit | Description |

|---|---|

| Increased reliability | Higher MTBF leads to fewer failures, reducing downtime and improving productivity. |

| Improved customer satisfaction | Longer operation times and fewer breakdowns enhance the quality of outputs, boosting satisfaction. |

| Customer loyalty | Enhanced reliability and satisfaction can result in increased loyalty and repeat business. |

Sobot's Voice/Call Center demonstrates this by delivering stable and reliable communication solutions, helping businesses build lasting relationships with their customers.

How to Calculate MTBF

The MTBF Formula

Formula: MTBF = Total Operating Time / Number of Failures

The formula for mean time between failures (MTBF) is straightforward. Divide the total operating time of a system by the number of failures it experiences during that time. For example, if a system runs for 1,000 hours and encounters 5 failures, the MTBF would be 200 hours.

This formula is rooted in reliability engineering principles. It assumes failures occur randomly over time, following an exponential distribution. This statistical model predicts that 63% of equipment will fail by the calculated MTBF. Accurate failure data is essential for this calculation. Operational logs and maintenance records provide the necessary information to ensure the reliability of the metrics.

MTBF serves as a critical reliability metric for systems like Sobot's Voice/Call Center. With a 99.99% uptime, Sobot exemplifies how robust MTBF calculations can guide maintenance planning and minimize downtime.

Example Calculation

Step-by-step example of calculating MTBF for a customer service system

Imagine a customer service system operates for 10,000 hours and experiences 50 failures during that period. Here's how you calculate MTBF:

- Determine Total Operating Time: The system ran for 10,000 hours.

- Count the Number of Failures: There were 50 failures recorded.

- Apply the Formula: Divide the total operating time by the number of failures:

MTBF = Total Operating Time / Number of Failures MTBF = 10,000 hours / 50 failures MTBF = 200 hours

This result means the system operates for an average of 200 hours between failures.

Interpreting results to improve reliability in systems like Sobot's Voice/Call Center

A calculated MTBF of 200 hours highlights areas for improvement. By analyzing failure patterns, you can schedule preventive maintenance to extend the MTBF. For customer-facing systems like Sobot's Voice/Call Center, this approach ensures consistent service delivery. With features like real-time monitoring and AI-powered analytics, Sobot helps businesses track reliability metrics and reduce downtime effectively.

Strategies to Improve MTBF

Preventive Maintenance Practices

Scheduling regular inspections and servicing.

Regular inspections and servicing form the backbone of preventive maintenance strategies. By scheduling maintenance just before the expected mean time between failures (MTBF), you can anticipate maintenance needs and reduce the risk of unexpected breakdowns. Usage-based scheduling, which adapts to operational hours, ensures timely servicing even under variable MTBF conditions. This approach not only minimizes unscheduled downtime but also enhances the quality of your equipment's performance. High MTBF reflects system robustness, and proactive maintenance helps sustain this reliability. For example, industries that implement preventive maintenance schedules report significant improvements in operational efficiency and reduced failure rates.

Using data analytics to predict and prevent failures.

Data analytics plays a crucial role in helping you predict failure rates and optimize equipment reliability. By tracking equipment performance, you can identify patterns and anticipate maintenance needs before issues arise. Predictive maintenance, powered by analytics, reduces downtime by servicing equipment proactively. For instance, real-time monitoring tools like Sobot's Voice/Call Center analytics provide actionable insights. These tools detect anomalies early, allowing you to address potential failures promptly. Such data-driven strategies not only improve MTBF but also ensure consistent system performance.

Optimizing System Design

Designing systems with reliability in mind.

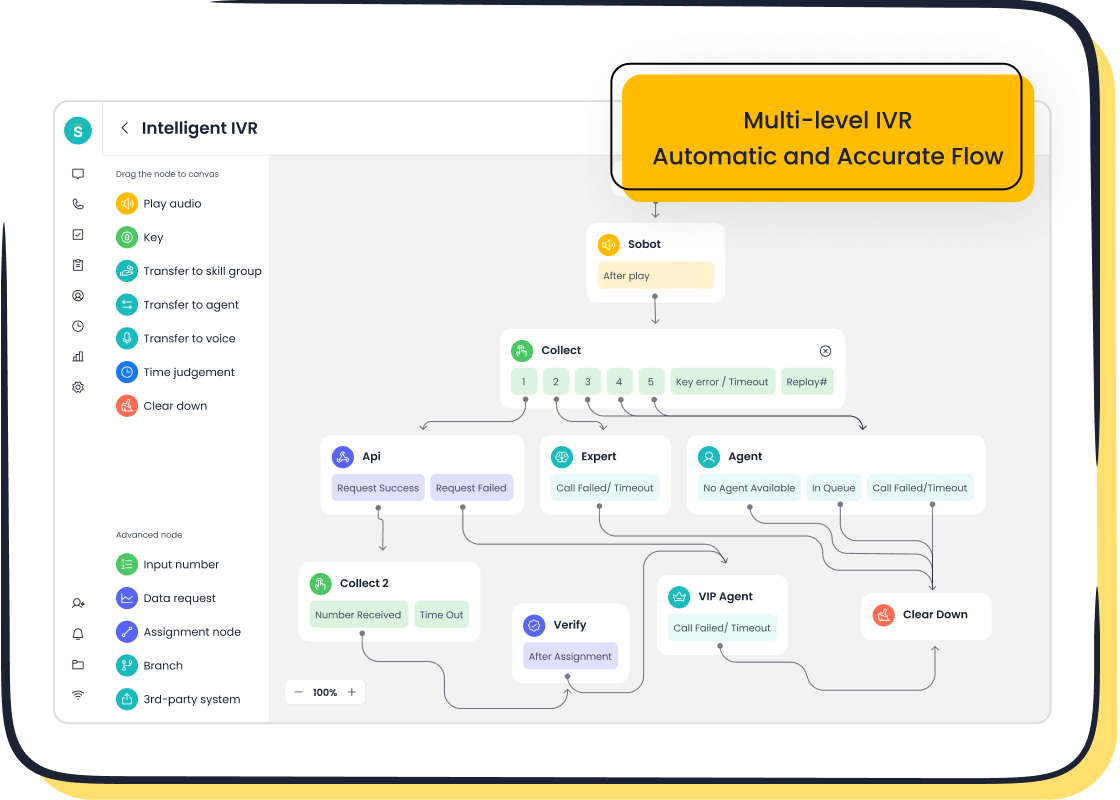

Designing systems with reliability as a priority ensures fewer failures and longer operational lifespans. A well-designed system incorporates redundancy, robust components, and streamlined workflows to minimize stress on critical parts. For example, Sobot's Voice/Call Center integrates intelligent IVR and AI-powered voicebots to reduce system strain and enhance reliability. By focusing on quality during the design phase, you can optimize equipment reliability and extend the mean time between failures.

Using high-quality components to reduce failure rates.

High-quality components significantly impact the reliability of your systems. Investing in durable materials and advanced technologies reduces the likelihood of failures, ensuring smoother operations. For instance, industries that prioritize quality in their components often experience longer MTBF and lower maintenance costs. Sobot's solutions, with their 99.99% uptime, exemplify how using premium components can enhance system reliability and customer satisfaction.

Leveraging Technology for MTBF Improvement

Using monitoring tools like Sobot's Voice/Call Center analytics.

Monitoring tools provide real-time insights into equipment performance, helping you track equipment performance and anticipate maintenance needs. Features like automated alerts and detailed reports enable you to act before failures occur. Sobot's Voice/Call Center analytics, for example, combines MTBF data with other metrics to support data-driven decisions. This approach ensures proactive maintenance and enhances system reliability.

Employing AI and machine learning for predictive maintenance.

AI and machine learning revolutionize predictive maintenance by analyzing historical and real-time data to forecast failures. For instance, SolarTech Solutions achieved a 64% increase in MTBF by implementing AI-driven predictive maintenance. These technologies not only predict failure rates but also recommend specific actions to prevent them. Sobot's AI-powered tools, such as its Voice/Call Center, leverage machine learning to enhance reliability and reduce downtime, ensuring seamless operations.

Training and Process Enhancements

Educating staff on best practices for system operation

Training your team is one of the most effective ways to improve system reliability and extend MTBF. Well-trained staff can quickly identify failure modes and respond effectively to issues. This reduces downtime and ensures smoother operations. For example, technicians who understand system workflows can troubleshoot problems faster, preventing minor issues from escalating into major failures.

Metrics like MTBF and Mean Time to Repair (MTTR) confirm the value of training. Tracking these metrics helps you evaluate how well your team handles maintenance and repairs. A trained team can reduce MTTR, which directly impacts MTBF by minimizing the time systems remain non-operational.

Sobot's Voice/Call Center provides tools like real-time monitoring and analytics. These features help your team track system performance and identify potential issues early. By combining these tools with proper training, you can ensure your systems operate reliably and meet customer expectations.

Streamlining processes to minimize human error

Human error is a common cause of system failures. Streamlining your processes can significantly reduce these errors and improve MTBF. Simplified workflows and clear guidelines ensure your team performs tasks consistently and accurately. For instance, automating repetitive tasks like call routing or data entry minimizes the risk of mistakes.

Optimized processes also improve maintenance strategies. By scheduling preventive maintenance based on MTBF data, you can address potential issues before they lead to failures. This approach reduces unplanned downtime and enhances system reliability.

Sobot's Voice/Call Center supports process optimization with features like intelligent IVR and AI-powered voicebots. These tools automate routine tasks and provide actionable insights, helping your team focus on critical operations. With streamlined processes and reliable systems, you can deliver consistent service and build customer trust.

MTBF and Customer Satisfaction

The Link Between Reliability and Customer Experience

How reliable systems enhance customer trust and loyalty.

Reliability is the foundation of customer trust. When your systems operate without interruptions, customers feel confident in your ability to deliver consistent service. A high mean time between failures (MTBF) ensures fewer breakdowns, which translates to smoother operations and happier customers. For example, businesses that improve MTBF often see a direct boost in customer loyalty.

| Benefit | Description |

|---|---|

| Increased reliability | Enhancing MTBF leads to fewer failures, resulting in more reliable systems and components. |

| Improved customer satisfaction | Reducing breakdowns and outages allows businesses to deliver higher-quality outputs, boosting customer satisfaction and loyalty. |

By maintaining high availability, you can meet customer expectations and foster long-term relationships. Sobot's Voice/Call Center, with its 99.99% uptime, exemplifies how reliable systems build trust. Customers value continuous operation, and a dependable platform ensures they return for future interactions.

The role of MTBF in meeting customer expectations in contact centers.

In contact centers, MTBF plays a critical role in meeting customer expectations. A higher MTBF means fewer disruptions, ensuring your team can handle inquiries without delays. Studies confirm that increasing MTBF improves customer satisfaction across industries.

| Source | Evidence |

|---|---|

| Allied Reliability | MTBF is a valuable metric that helps organizations ensure reliability, availability, and performance, leading to improved customer satisfaction. |

| IBM | Extending operation time and reducing breakdowns can produce higher-quality outputs, improving customer satisfaction and loyalty. |

| Shifton | Increasing MTBF results in greater customer satisfaction and cost savings. |

| A high MTBF in manufacturing leads to less downtime and higher customer satisfaction. |

By leveraging MTBF data, you can optimize your contact center's performance and exceed customer expectations.

MTBF in Sobot's Voice/Call Center

Ensuring uptime and reliability for customer support systems.

Sobot's Voice/Call Center demonstrates the importance of MTBF in ensuring uptime and reliability. Metrics like uptime percentage and MTBF validate the platform's performance:

- Mean Time Between Failures (MTBF): This metric reflects the average time the system operates without failure, showcasing its reliability.

- Uptime Percentage: With 99.99% uptime, Sobot ensures your customer support systems remain operational, meeting the demands of continuous operation.

These metrics highlight how Sobot's solutions maintain availability, enabling your team to deliver uninterrupted service. Reliable systems like these enhance customer satisfaction and strengthen your brand's reputation.

Reducing frustration caused by system outages in customer interactions.

System outages can frustrate customers and damage trust. A high MTBF minimizes these disruptions, ensuring smooth interactions. Monitoring MTBF helps you address weaknesses proactively, improving system resilience and reducing downtime.

- Maintaining a high MTBF positively impacts service availability and user experience.

- A higher MTBF leads to fewer outages, minimizing user frustration.

Sobot's Voice/Call Center leverages advanced analytics to track MTBF and uptime. This proactive approach ensures your systems operate reliably, reducing customer frustration and enhancing satisfaction.

Tracking mean time between failures (MTBF) is essential for ensuring system reliability and meeting customer expectations. It reduces downtime, improves productivity, and enhances safety across industries. Businesses that focus on MTBF also benefit from lower maintenance costs, better quality control, and longer equipment lifespans. High MTBF values reflect reliable systems, which foster customer trust and loyalty while saving costs. For example, improving MTBF minimizes disruptions, leading to fewer repairs and replacements.

Sobot's Voice/Call Center exemplifies how advanced tools can help businesses achieve higher MTBF. With features like real-time monitoring and AI-powered analytics, Sobot ensures reliable operations and consistent service delivery. These solutions not only reduce operational disruptions but also strengthen customer relationships, making Sobot a trusted partner for businesses aiming to enhance reliability.

FAQ

What is the role of MTBF in maintaining equipment reliability?

MTBF helps you predict how long your equipment will operate before failing. By tracking this metric, you can schedule maintenance proactively, reducing unexpected breakdowns. For example, Sobot's Voice/Call Center uses MTBF data to ensure its systems maintain a 99.99% uptime, delivering reliable service to customers.

How does MTBF reduce operational costs?

MTBF allows you to plan maintenance schedules effectively. This reduces emergency repairs and extends the lifespan of your equipment. Predictive maintenance based on MTBF data saves costs by preventing failures. For instance, industries using MTBF-driven strategies report up to 25% cost reductions in maintenance.

Can MTBF improve customer satisfaction?

Yes, reliable equipment with a high MTBF ensures uninterrupted service, which enhances customer satisfaction. For example, Sobot's Voice/Call Center minimizes downtime through its robust design and analytics, helping businesses maintain smooth customer interactions and build trust.

How do you calculate MTBF for your equipment?

To calculate MTBF, divide the total operating time by the number of failures. For example, if your equipment operates for 1,000 hours and fails twice, the MTBF is 500 hours. This metric helps you assess reliability and plan maintenance effectively.

Why is MTBF important for customer-facing systems?

Customer-facing systems rely on reliable equipment to deliver consistent service. A high MTBF ensures fewer disruptions, improving customer trust. Sobot's Voice/Call Center exemplifies this with its 99.99% uptime, ensuring seamless operations and enhancing customer experiences.

See Also

Essential Strategies for Effective Call Center Quality Management

Comprehensive Overview of Call Center QA Software Solutions

Understanding Quality Management Systems in Call Centers

Enhancing Call Center Efficiency Through Effective Monitoring

Ten Strategies to Improve Customer Satisfaction in Live Chat