Guide to Using Cost Per Order Calculators Effectively

Have you ever wondered how much it really costs to fulfill each customer order? That’s where cost per order (CPO) calculators come in. These tools help you figure out the total expenses tied to delivering goods or services, from packaging to shipping. For businesses in eCommerce, retail, or logistics, understanding cost per order is essential. It reveals how profitable your operations are and where you can save money.

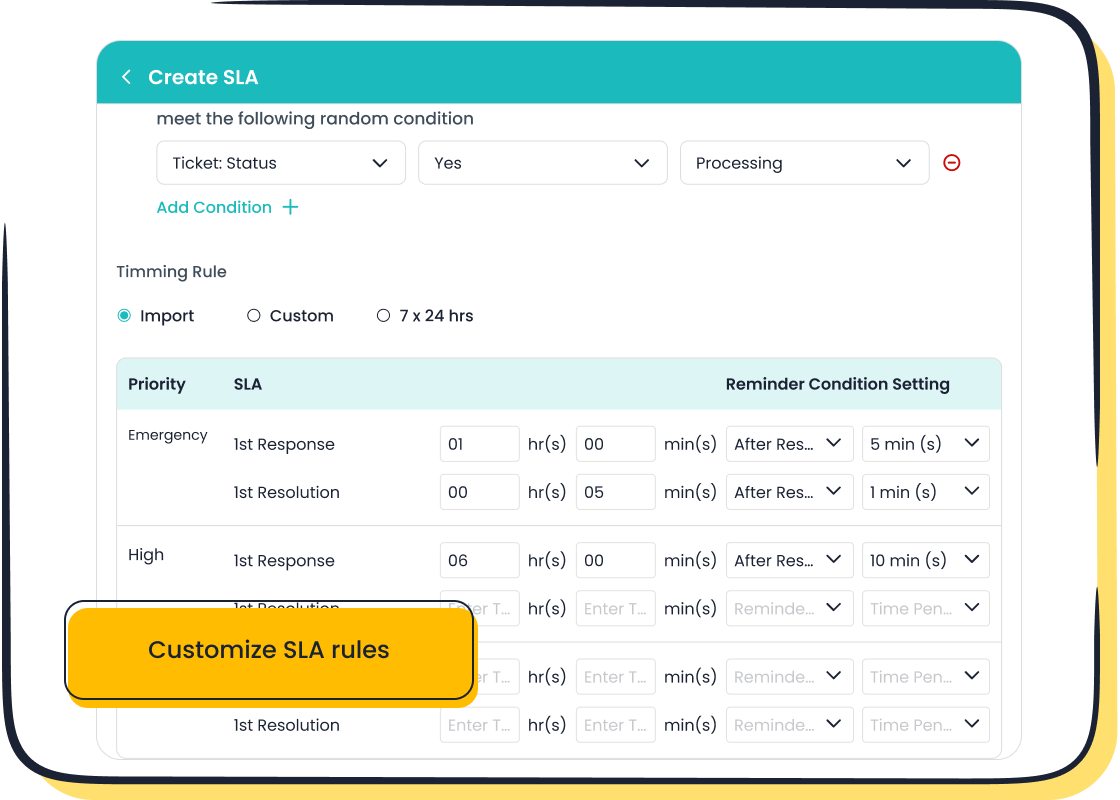

Accurate calculations matter. They let you spot inefficiencies and make smarter decisions. Tools like Sobot's Ticketing System simplify this process by automating workflows and tracking costs across channels. With features like SLA management and analytics, you can ensure every dollar spent is accounted for.

Understanding Cost Per Order (CPO)

What Is Cost Per Order?

Definition and its significance in customer service and business operations

Cost per order (CPO) is the total expense incurred to fulfill a single customer order. It includes everything from direct costs like shipping and packaging to indirect costs such as labor and software. For businesses, understanding this metric is crucial. It helps you evaluate profitability, refine pricing strategies, and identify areas where you can cut costs.

In customer service, CPO plays a vital role. A lower cost per order often means streamlined operations, which can lead to faster delivery times and happier customers. Tools like Sobot's Ticketing System can help you track these costs efficiently by automating workflows and providing real-time analytics.

Examples of industries benefiting from cost per order analysis

Many industries rely on cost per order analysis to stay competitive. For example:

- eCommerce: Tracks fulfillment costs to optimize pricing and shipping strategies.

- Logistics: Identifies inefficiencies in delivery routes and warehouse operations.

- Retail: Balances inventory holding costs with customer demand.

Components of Cost Per Order

Direct costs (e.g., materials, labor, shipping)

Direct costs are the expenses directly tied to fulfilling an order. These include:

- Product costs: The price of goods sold.

- Shipping and packaging: Costs for delivering and protecting the product.

- Handling and fulfillment: Labor and resources used to prepare the order.

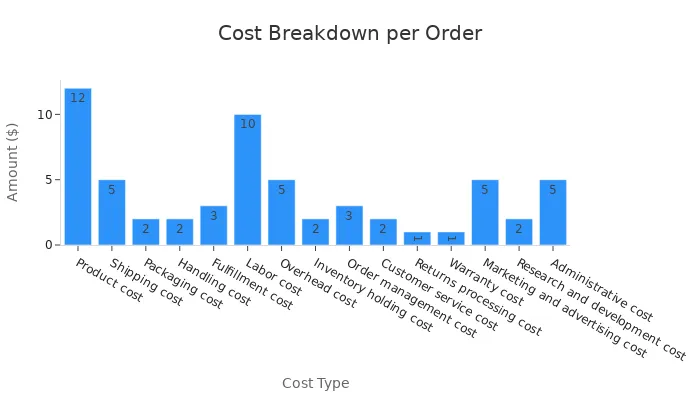

For instance, if your product costs $12, shipping is $5, and packaging is $2, your total direct cost is $19.

Indirect costs (e.g., rent, utilities, software like Sobot's Ticketing System)

Indirect costs are less obvious but equally important. These include:

- Labor and overhead: Salaries, utilities, and rent.

- Customer service tools: Software like Sobot's Ticketing System, which automates ticket management and reduces manual effort.

- Marketing and R&D: Expenses for promoting products and improving services.

Here’s a detailed breakdown:

| Cost Type | Amount |

|---|---|

| Direct Costs | |

| Product cost | $12 |

| Shipping cost | $5 |

| Packaging cost | $2 |

| Handling cost | $2 |

| Fulfillment cost | $3 |

| Total Direct Cost | $24 |

| Indirect Costs | |

| Labor cost | $10 |

| Overhead cost | $5 |

| Inventory holding cost | $2 |

| Order management cost | $3 |

| Customer service cost | $2 |

| Returns processing cost | $1 |

| Warranty cost | $1 |

| Marketing and advertising cost | $5 |

| Research and development cost | $2 |

| Administrative cost | $5 |

| Total Indirect Cost | $40 |

| Total Cost per Order | $64 |

Why Cost Per Order Matters

Impact on pricing strategies and customer satisfaction

Your cost per order directly influences your pricing. If your costs are too high, you may need to raise prices, which could deter customers. On the other hand, a well-optimized CPO allows you to offer competitive pricing while maintaining profitability.

Satisfied customers are another benefit. Lower costs often mean faster delivery and better service. For example, J&T Express used Sobot's solutions to reduce costs by 50%, improving both efficiency and customer satisfaction.

Role in identifying inefficiencies and improving operational margins

High CPO often signals inefficiencies in your operations. It could be due to expensive shipping methods, poor inventory management, or outdated tools. By analyzing your CPO, you can pinpoint these issues and take corrective action.

Here’s how technology helps:

| Technology Role | Description |

|---|---|

| SCM Software | Automates processes, reduces manual errors, and provides real-time tracking of costs, enhancing CPO calculation accuracy. |

| Advanced Analytics | Offers deep insights into operations, aiding in effective CPO management and optimization. |

By leveraging tools like Sobot's Ticketing System, you can automate workflows, track costs, and improve your operational margins.

Calculating Cost Per Order: A Step-by-Step Guide

Understanding how to calculate your cost per order is crucial for managing expenses and boosting profitability. Let’s break it down into a simple step-by-step guide.

Step-by-Step Guide

Identify all direct costs

Start by listing every direct expense tied to fulfilling an order. These include product costs, shipping, packaging, and handling. For example, if you sell a gadget, your direct costs might include $12 for the product, $5 for shipping, and $2 for packaging.

Account for indirect costs

Next, add up your indirect costs. These are expenses that support your operations but aren’t directly tied to a single order. Think of things like rent, utilities, and software. Tools like Sobot's Ticketing System can help you track these costs by automating workflows and providing detailed analytics.

Divide total costs by the number of orders

Finally, sum up your direct and indirect costs, then divide by the total number of orders. For instance, if your total costs for the month are $19,200 and you fulfilled 300 orders, your cost per order is $64.

Example Calculation

Simple example with hypothetical numbers

Let’s say your direct costs per order are $24, including $12 for the product, $5 for shipping, and $7 for packaging and handling. Your indirect costs, such as labor and overhead, total $40 per order. Adding these together gives you a total cost per order of $64.

Adjusting for variable costs and seasonal fluctuations

Costs can vary depending on demand. During peak seasons, shipping costs might rise, or you may need extra labor. Regularly updating your calculations ensures accuracy. For example, if your shipping costs increase by $2 during the holidays, your new cost per order would be $66.

Tools to Simplify the Process

Online calculators and spreadsheet templates

You can use online calculators or spreadsheet templates to streamline the process. These tools let you input your costs and automatically calculate your cost per order. They’re great for small businesses or those just starting out.

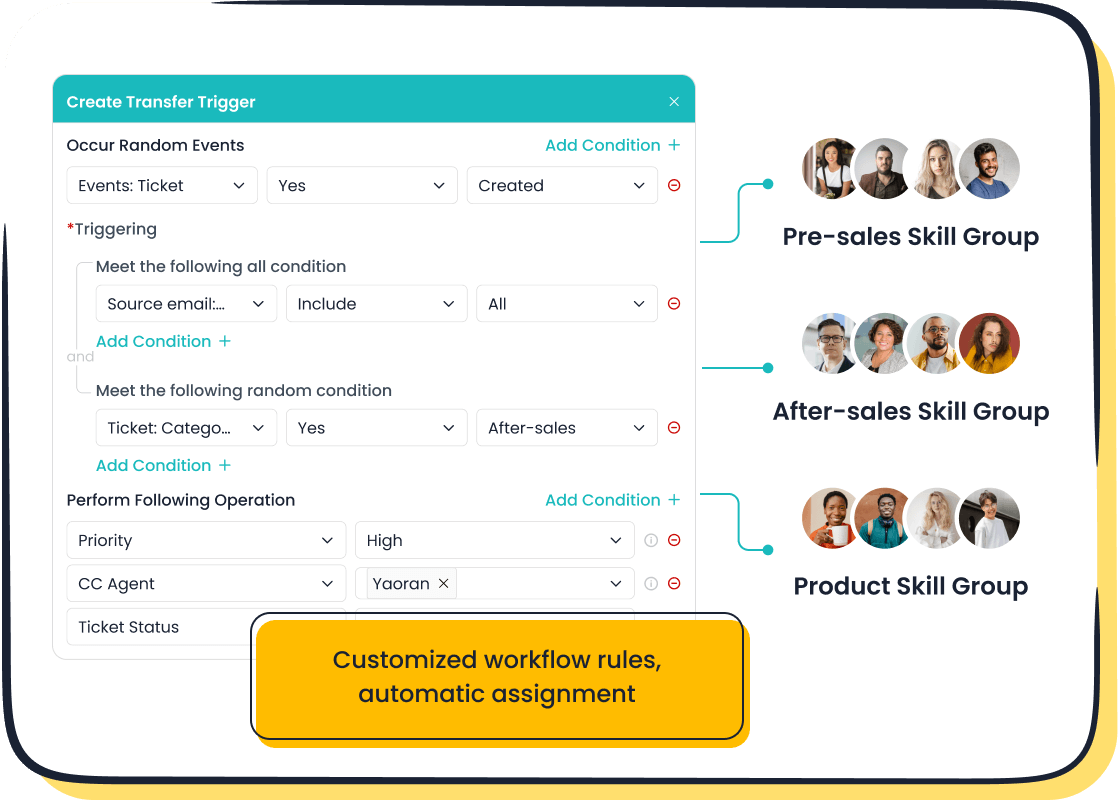

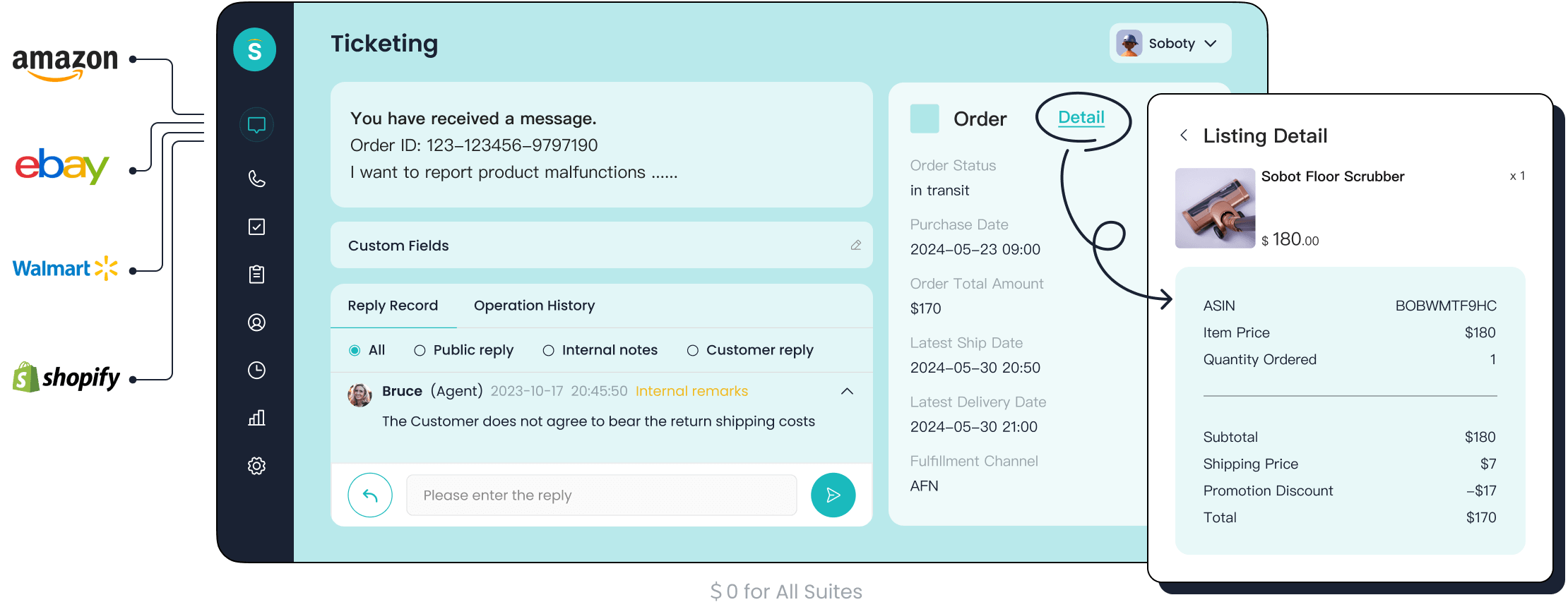

Advanced solutions like Sobot's Ticketing System for automated tracking

For larger operations, advanced tools like Sobot's Ticketing System are invaluable. This system automates cost tracking across channels, integrates with platforms like Shopify, and provides real-time analytics. It simplifies the entire process, saving you time and reducing errors.

By following this step-by-step guide and leveraging the right tools, you can master the methods for calculating cost per order and make data-driven decisions to improve your business.

Common Mistakes to Avoid When Calculating Cost Per Order

Even with the best intentions, mistakes can creep into your cost per order calculations. These errors can distort your understanding of expenses and lead to poor business decisions. Let’s explore some common pitfalls and how to avoid them.

Overlooking Indirect Costs

Examples of commonly missed expenses

It’s easy to focus solely on direct costs like shipping and packaging while ignoring indirect costs. However, these hidden expenses can add up quickly. For example:

- Opportunity costs from delayed projects or missed sales.

- Administrative costs like rent, utilities, and software subscriptions.

In fact, indirect spend can account for up to 40% of total expenditures. Strategic management of these costs can save you up to 25%, improving efficiency and product quality.

| Cost Type | Description | Financial Impact |

|---|---|---|

| Direct Costs | Salaries paid during unproductive meetings | Cumulative loss of $399 billion in 2019 |

| Indirect Costs | Delayed timelines or missed sales opportunities | Harder to quantify but critical to track |

Ensuring comprehensive cost tracking with tools like Sobot

To avoid missing these expenses, use tools like Sobot's Ticketing System. It automates workflows and tracks costs across channels, ensuring no expense slips through the cracks.

Using Inaccurate Data

Consequences of incorrect inputs on customer service efficiency

Inaccurate data can wreak havoc on your cost per order calculations. If you underestimate costs, you might set prices too low, cutting into profits. Overestimating can make your products less competitive. Both scenarios hurt customer satisfaction and operational efficiency.

Tips for maintaining accurate records with automated systems

Automated systems like Sobot's Ticketing System help maintain accurate records. Features like SLA management and real-time analytics ensure your data stays reliable, reducing errors and saving time.

Ignoring Seasonal or Volume Variations

Adjusting calculations for fluctuating demand

Seasonal demand can significantly impact your cost per order. For instance, during the holidays, higher shipping and staffing costs can inflate expenses. Ignoring these variations can lead to inventory shortages or missed sales opportunities.

Importance of regular updates to cost per order metrics

Regularly updating your cost per order metrics is crucial. Retailers often face higher operating costs during peak seasons. By adjusting for these fluctuations, you can make better pricing and inventory decisions.

Pro Tip: Use advanced calculators or tools like Sobot's Ticketing System to factor in seasonal changes automatically. This ensures your calculations remain accurate year-round.

Strategies to Reduce Cost Per Order and Improve Profitability

Reducing your cost per order is key to improving profitability. By focusing on direct and indirect costs and enhancing operational efficiency, you can achieve better margins and deliver more value to your customers. Let’s explore some practical strategies.

Reducing Direct Costs

Negotiating with suppliers and streamlining processes

One of the most effective ways to reduce cost per order is by negotiating better terms with your suppliers. For example:

- A high-volume eCommerce retailer revamped its procurement strategy to address delayed deliveries and inconsistent quality.

- A boutique hotel chain in Southeast Asia streamlined its procurement to combat rising supply costs, improving competitiveness.

- A luxury fashion brand secured better terms while maintaining quality, despite escalating raw material costs.

Streamlining processes also helps. By optimizing workflows, you can minimize waste and improve time efficiency. This approach ensures you’re not just cutting costs but also maintaining quality and customer satisfaction.

Leveraging automation tools like Sobot's Ticketing System

Automation tools like Sobot's Ticketing System can significantly reduce direct costs. By automating ticket routing and customer inquiries, you save on labor and improve response times. The system’s integration with platforms like Shopify ensures seamless order management, helping you achieve optimal order quantity and reduce cost per order.

Managing Indirect Costs

Identifying and cutting unnecessary overhead

Indirect costs, such as rent and utilities, often go unnoticed. Conduct a full cost analysis to identify areas where you can cut back. For instance, switching to remote work or downsizing office space can save thousands annually.

Investing in cost-efficient technologies

Investing in automation pays off. Companies using automated procure-to-pay solutions have seen savings of 15-25% in transactions. Automation also reduces processing times from days to minutes, improving overall cost analysis accuracy. Tools like Sobot’s Ticketing System provide trusted analytics, helping you track and manage these costs effectively.

| Benefit | Details |

|---|---|

| Cost Savings | Automation reduces transaction costs by 15-25%. |

| Processing Time Reduction | Tasks that took days now take minutes. |

| Value Leakage Reduction | Automated systems cut value leakage by 3% annually. |

Enhancing Operational Efficiency

Automating repetitive tasks with AI-powered tools

Automation isn’t just about saving time—it’s about focusing on what matters. Studies show 85% of business leaders believe automation allows employees to prioritize strategic goals. For example, automating social media ads can save over six hours weekly. Sobot’s AI-powered Ticketing System automates repetitive tasks like ticket assignment, improving time efficiency and reducing errors.

| Metric | Evidence |

|---|---|

| Focus on Goals | 85% of leaders say automation helps employees focus on strategic tasks. |

| Time Savings | Automation saves over six hours weekly on tasks like social media ads. |

| Cost Reduction | Streamlined processes optimize resources and reduce costs. |

Training staff to reduce errors and improve customer satisfaction

Well-trained staff make fewer mistakes, which lowers your cost per order. Regular training sessions ensure your team understands the tools and processes in place. For instance, using Sobot’s Ticketing System becomes more effective when employees know how to leverage features like SLA management and canned responses. This not only reduces errors but also boosts customer satisfaction.

By implementing these strategies, you’ll not only reduce cost per order but also enhance your operational margins and customer experience.

Role of Technology in Calculating and Optimizing Cost Per Order

Benefits of Using Technology

Enhanced accuracy and efficiency in cost tracking

Technology has revolutionized how you calculate cost per order. Tools like procurement calculators and inventory management systems automate processes, reducing manual errors. For example, supply chain management software gathers precise data and tracks costs in real time. This ensures your cost per order (CPO) calculations are accurate and efficient.

Modern technologies also consolidate multiple legacy systems into one intelligent platform. By digitizing contracts and adopting eSourcing, businesses have seen improved procurement ROI. These advancements streamline workflows, helping you focus on strategic goals rather than tedious calculations.

Real-time reporting and data-driven insights

Real-time reporting is a game-changer for interpreting CPO results. With access to timely data, you can make informed decisions quickly. Advanced analytics highlight opportunities and risks, allowing you to adjust strategies on the fly. For instance, real-time insights into supplier performance can help you negotiate better terms, reducing your economic order quantity (EOQ).

By leveraging these tools, you gain a clearer picture of your operations. This clarity helps you optimize inventory management and refine your procurement calculator inputs for better results.

Sobot's Ticketing System: A Game-Changer

Features that simplify cost per order calculations

Sobot's Ticketing System takes the guesswork out of calculating CPO. It automates workflows, tracks costs across channels, and integrates seamlessly with eCommerce platforms. Features like SLA management and trusted analytics ensure every expense is accounted for.

For example, the system’s AI-powered ticketing automates repetitive tasks like ticket assignment. This reduces labor costs and improves efficiency. With multilingual support and smart notifications, you can manage global operations effortlessly.

Integration with customer service and e-commerce platforms

Sobot’s Ticketing System integrates with platforms like Shopify, unifying your customer service and order management. This integration simplifies the process of calculating EOQ and managing inventory. By consolidating data from multiple channels, you get a comprehensive view of your costs.

These features make Sobot’s solution ideal for businesses looking to optimize their economic order quantity and improve operational efficiency.

Integrating Cost Per Order Tools with Other Systems

Linking calculators with inventory and customer management software

Integrating your procurement calculator with inventory management software is essential. This connection ensures your EOQ calculations reflect real-time stock levels and demand forecasts. For example, linking your calculator to a customer management system helps you track order trends and adjust your strategies accordingly.

Using insights to refine customer service strategies

The insights from these integrations go beyond cost tracking. They help you refine your customer service strategies. For instance, if your data shows high returns during a specific season, you can adjust your inventory or improve product descriptions. Tools like Sobot’s Ticketing System provide actionable insights, enabling you to enhance customer satisfaction while reducing costs.

By integrating these systems, you create a streamlined process that supports both operational efficiency and customer-centric decision-making.

Understanding your cost per order (CPO) is more than just crunching numbers—it’s about unlocking insights that drive smarter decisions. By optimizing this metric, you can boost profitability, streamline operations, and deliver better customer experiences. Tools like Sobot's Ticketing System make this process seamless by automating workflows and providing real-time analytics.

Don’t stop there. Regularly review your calculations to adapt to changing costs and market trends. Staying proactive ensures your business remains competitive and profitable in the long run.

Ready to take control of your costs? Start optimizing today!

FAQ

1. What is the best way to calculate cost per order for a small business?

For small businesses, start by listing all direct and indirect costs. Use simple tools like spreadsheets or online calculators. If you want to save time, consider automation tools like Sobot's Ticketing System. It tracks costs across channels and provides real-time analytics, making calculations easier.

2. How often should I update my cost per order calculations?

You should update your cost per order regularly, especially during seasonal changes or when costs fluctuate. For example, holidays often increase shipping expenses. Tools like Sobot's Ticketing System can automate updates, ensuring your calculations stay accurate year-round.

3. Can technology really help reduce cost per order?

Absolutely! Automation tools like Sobot's Ticketing System streamline workflows, reduce manual errors, and track costs efficiently. For instance, J&T Express reduced costs by 50% using Sobot’s solutions. This shows how technology can significantly improve profitability.

4. What are some common mistakes to avoid when calculating cost per order?

Avoid overlooking indirect costs like software subscriptions or rent. Using outdated data is another common error. Tools like Sobot's Ticketing System help you track all expenses and maintain accurate records, ensuring no costs are missed.

5. How does Sobot's Ticketing System simplify cost tracking?

Sobot's Ticketing System automates ticket management, integrates with platforms like Shopify, and provides trusted analytics. It tracks costs across channels, helping you calculate cost per order with precision. Its features save time and improve operational efficiency.

💡 Pro Tip: Regularly review your cost per order metrics to adapt to market changes and maintain profitability.

See Also

Comparative Guide To Live Chat Support Expenses

Effective Strategies For Managing Live Chat Representatives

Comprehending The Expenses Of Live Chat Outsourcing